The manufacturing process known as 3D printing is considered one of the most promising and rapidly emerging technologies with a multitude of applications across different industries.

Today, the market is full of 3D companies offering various 3D printing services and applications ranging from rapid prototyping, medical device solutions, Aerospace manufacturing, and low volume production to manufacturing of large models, props, and costumes used in the movie and entertainment industry.

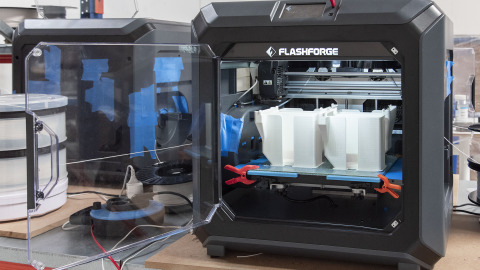

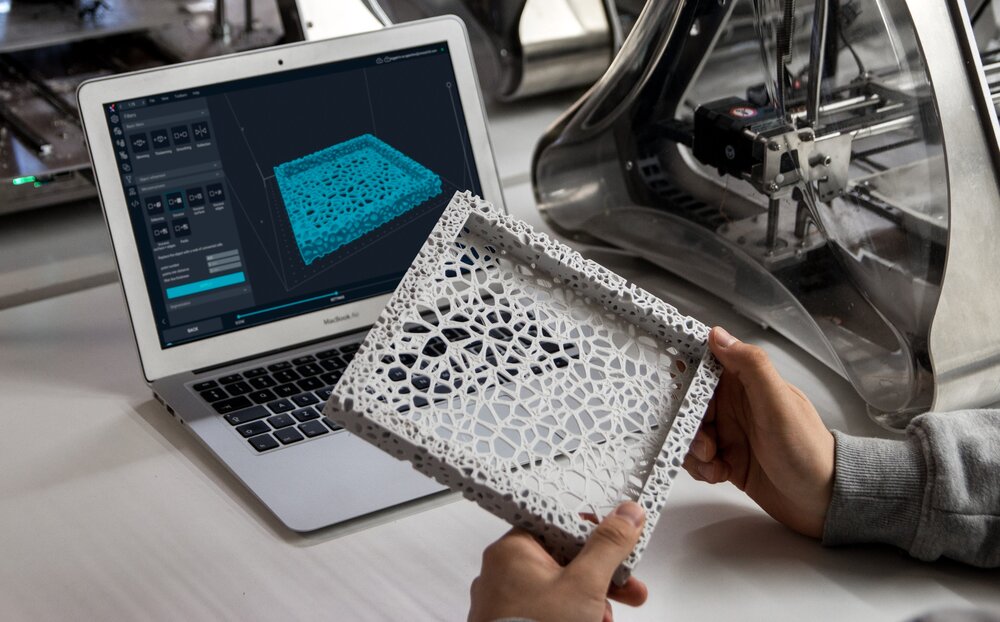

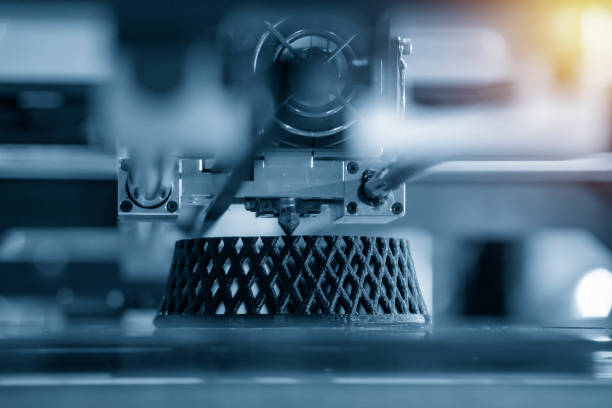

This technology involves the additive layering of materials fused together to construct a physical product from CAD data or digital files.

Benefits and Advantages of 3D Printing

Since its inception in the 1980s, 3D printing and advanced manufacturing services have evolved into a much more viable manufacturing process that offers guaranteed quality parts at affordable prices and fast lead times.

Companies across the globe have seen the potential and advantages of this technology over traditional modes of production. The benefits this technology brings to various industries are huge.

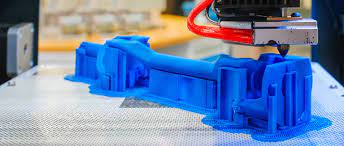

First, it allows users to produce parts or products with complex designs and geometries, which are difficult or impossible for traditional methods to fabricate. It also allows users with a limited experience to alter designs and create customized parts.

3D services also save on tooling costs and provide better lead times. The reduced production costs can be boiled down to three key advantages: Zero tooling, zero-cost complexity, and reduced labor.

The benefits and versatility of this technology are crucial for industries such as aerospace and automotive, where it can produce lightweight and complex parts. The weight saving this technology offers can result in fuel reductions and a better environmental impact.

Range of 3D Printing Services

Every 3D company offers definitive ranges of 3D services, including selective laser melting, laser deposition, concept modeling, additive manufacturing, rapid prototyping, parts production manufacturing tools and aids, and more.

Some companies even developed a product development cycle to help their clients accelerate their product development, elevate quality, and lower costs. With the help of this system, clients are empowered to work smarter, think faster, and innovate more freely

How to Choose the Right Print Service for Your Needs

There are several factors to consider when weighing up the print services and agencies out there. Here are the chief considerations to keep in mind when choosing which 3D printing service to use.

• Material Use

• Ability to Handle Batch Production

• Manufacturing/Production Cost

• Turnaround Time

• Privacy Policy, Terms, Conditions, and Certifications

Where is 3D Printing Technology Heading in the Future?

As 3D printing technology and services continue to advance, it could standardize the manufacture of goods. With 3D printers becoming faster and more sophisticated, they will be able to match other manufacturing techniques for mass production and work on large-scale production projects.

And as the cost of 3D printing also reduces, its use and applications will spread outside of industrial use into homes, schools, and other landscapes.