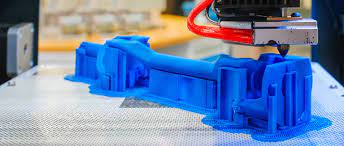

Three-dimensional printing has been a significant buzz term over the past decade and is also a good factor. Though initially created for product prototyping functions, modern 3D printing technology has greatly advanced to the part where it has become a principal in various sectors.

While clearly, this printing technology has been confirmed advantageous in the aerospace, medical, and tool-making arenas considering its creation, there is one other potential poised to burst out: the building and construction market.

With these printers now efficient in publishing structure wall surfaces and handling cement, such technology can aid to re-shape construction as we understand it. However, is such printing in the field of construction simply a short-lived trend, or does it have genuine staying power as a modern technology that can function as an essential lasting solution?

3D Printers in Construction

Why is this printing technology acquiring a lot of noise in the world of construction? As the market faces a boosting burden to meet limited timetables and budget plans, businesses seek new developments to help load the spaces. Three-dimensional printing in the field of construction supplies a substantial capacity to increase competence in the structure sector, consisting of adhering to methods. Listed below, we will explore precisely how 3D printers have been already making waves in construction and what the future looks like.

Speed

This printing technology has proven that it could build a building or home in a few days. That is a greatly faster duration than conventional building, which could take months or even years to build a commercial structure.

Waste Decrease

While this 3D printing won’t resolve every building and construction waste problem, it could help. Such is mainly because three-dimensional printing is a type of additive production procedure that only utilizes as much product as necessary to produce a framework. When partnered with various procedures to lessen waste and constructing approaches like prefabrication and lean building, the possibility of a no-waste building appears even more likely.

Layout Flexibility

Among the significant aspects of three-dimensional printing is design flexibility. Engineers can develop complex layouts that are not unattainable, pricey, or laborious to produce by traditional construction indicates. This can permit much more development and imagination in the industrial construction space.

Does printing in the building have real remaining power? From what we have seen, the promise is vital. Generally, the possibility of three-dimensional printing is too great to neglect. While the market might never reach a point where it is explicitly used, it is just an issue of time that the technology will undoubtedly be improved and also advance considerably. In general, three-dimensional printing is positioned to be a viable solution that provides critical benefits in price, financial savings, and environmental friendliness for our building’s future. With this, we can expect to see more great things happen- all thank this technology and the benefits it has to offer.